Measurement

Web inspection

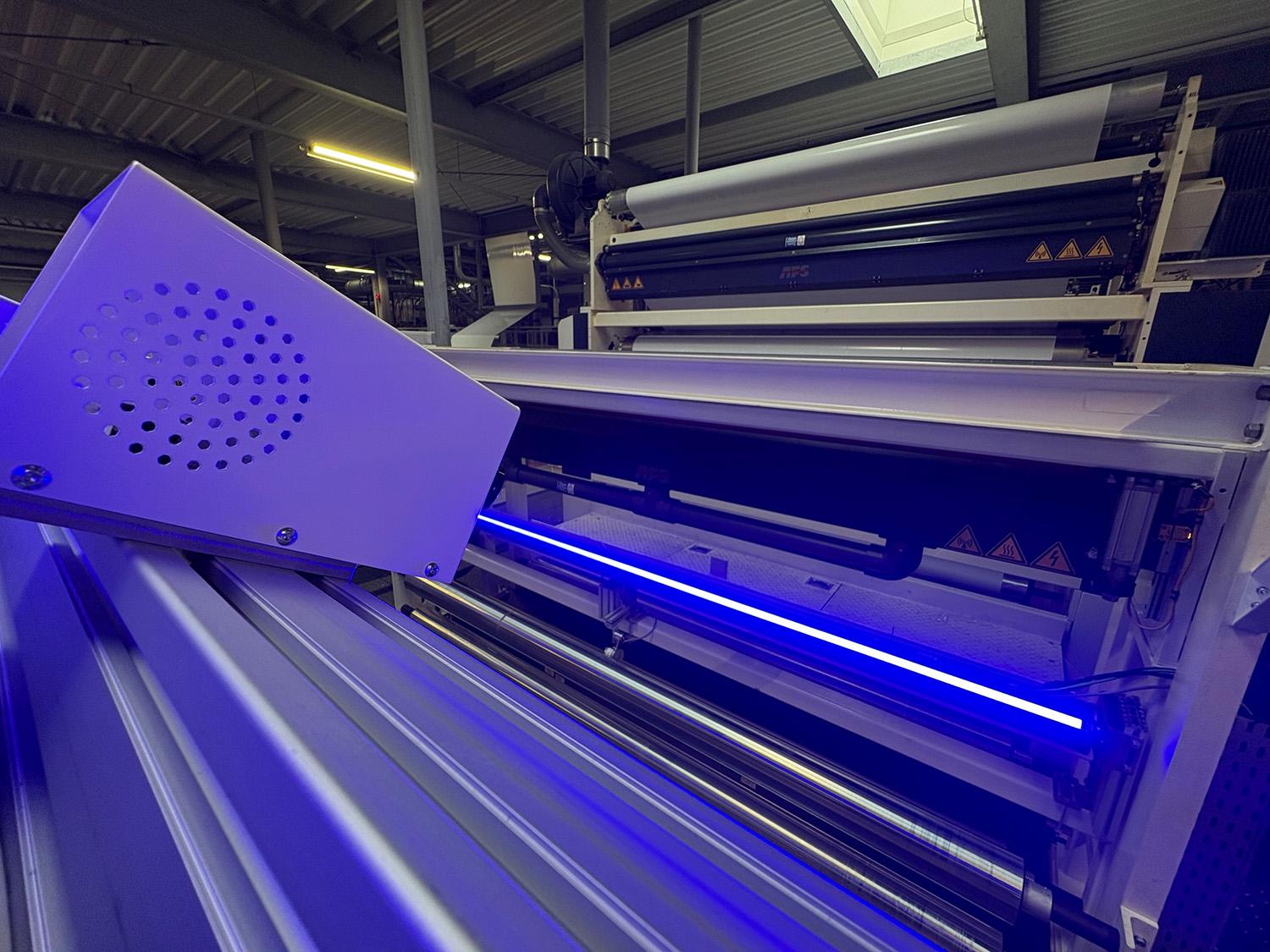

With KDvision-Inspect, you can monitor the quality of your blown film directly during the production process. The camera-based inspection system detects defects such as inclusions, gels, or streaks in real time and classifies them automatically.

This gives you maximum transparency and control over your production: defects are immediately detected, documented, and can thus be specifically remedied by your operators. This not only ensures consistently high quality, but also more efficient use of materials and more sustainable processes.

Ideal for applications with the highest demands on quality, traceability, and process reliability—KDvision-Inspect is your solution for future-proof blown film production.

KDvision-Inspect is suitable for both new installations and for upgrading existing systems. We would be happy to advise you.

Easy to

operate

The intuitive user interface allows for quick familiarization and is convenient use—even without in-depth technical knowledge.

AI-based

defect recognition

With the help of a specially developed neural network, defects are detected and classified precisely and reliably – for maximum quality assurance.

Modular design &

attractive price

Thanks to its modular system design, KDvision-Inspect can be flexibly adapted to your requirements – and at a particularly economical price-performance ratio.

Easy operation thanks to latest technology

With KDvision-Inspect, confusing user interfaces and cumbersome mouse and keyboard operation are a thing of the past. Instead, you benefit from intuitive and user-friendly operation.

The fully touch-based control system is operated via a large 27″ display, which presents all data in a clear and understandable way. Functions such as creating new productions are intuitive and easy to learn.

Thanks to its ease of use and short training period, KDvision-Inspect enables your plant operators and quality engineers to work smoothly and efficiently – right from day one.

Everything at a glance: In 4 sections

1. Header bar

The header bar permanently displays the most important information about current production.

2. Defect map

The defect map clearly displays all detected defects. The defect classes and sizes are visible at a glance.

3. Defect overview and details

The defect overview shows images of the most recently detected defects. By clicking on the defect image, the user can obtain further information.

4. Statistics

A glance at the statistics immediately reveals how good the production quality has been over a longer period of time and which defect classes dominate.

Precise and flexible defect detection – thanks to AI

KDvision-Inspect relies on a neural network developed in-house by Kdesign, based on decades of expertise in blown film extrusion.

This innovative technology enables absolutely precise detection of film defects and can be quickly and flexibly adapted to your individual requirements. With the help of deep learning, new defect classes can be easily created, allowing you to precisely distinguish between the defects that are relevant to you.

The result: Optimal quality assurance through state-of-the-art AI technology – perfectly tailored to your needs.

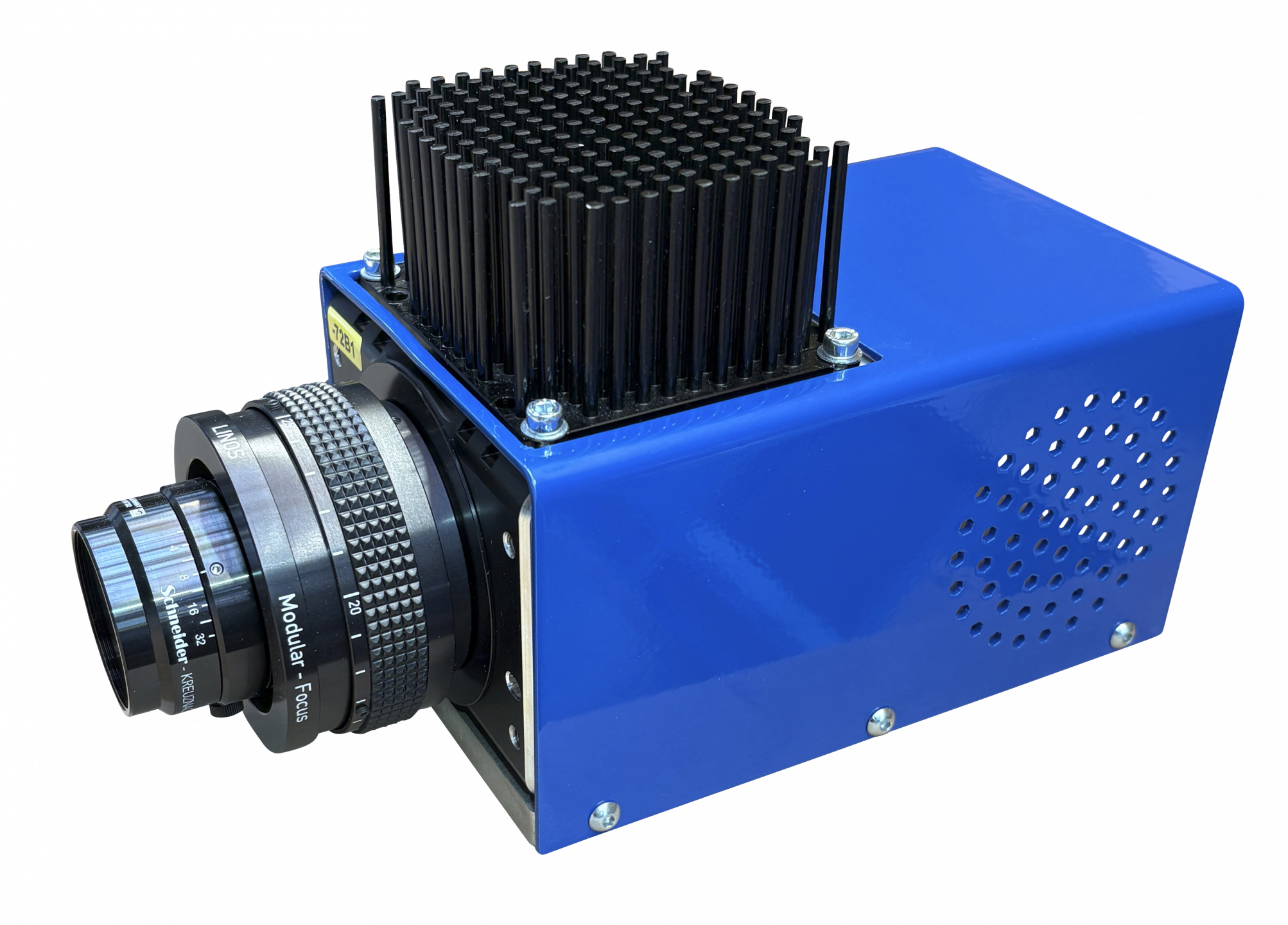

Reliable technology

At Kdesign, reliability is our top priority. That’s why we only use high-quality, durable components that guarantee maximum operational reliability even under demanding conditions. This robust technology ensures high availability and minimizes downtime – for smooth and efficient operation of your systems.

Technical data

KDvision-Inspect combines powerful hardware with intelligent software for reliable and precise in-line inspection in blown film production.

Technical features

- High-resolution cameras with powerful LED lighting for optimal image quality

- Real-time detection through contrast-based image analysis

- Resolution: up to 100 µm

- Web speed: up to 200 m/min

- Continuous monitoring without interrupting the production process

- Reliable AI-based classification of defect types

Detectable defect types

- Surface defects: gels, fisheyes, streaks, holes, inclusions

- Contaminants: e.g., insects, particles

- Mechanical faults: folds, creases

- Thanks to AI technology, customer-specific error classes can be created within minutes.