Calibration

Bubble & width control

With our solutions for controlling the IBC air and film width, you save time and money every time you start up and change the format of your blown film line, because Kdesign offers the most responsive and stable bubble control on the market. Our practical control and operating concept simplifies production set-up.

Kdesign systems are suitable for installation in new and existing lines. All systems can also be easily installed in calibration baskets from other manufacturers.

Fastest

adjustment

Particularly fast adjustment saves you time and money with every start-up process and format change.

Best width

stability

Reduce your waste. Kdesign’s bubble control keeps your film width reliably constant at all times.

Highest

reliability

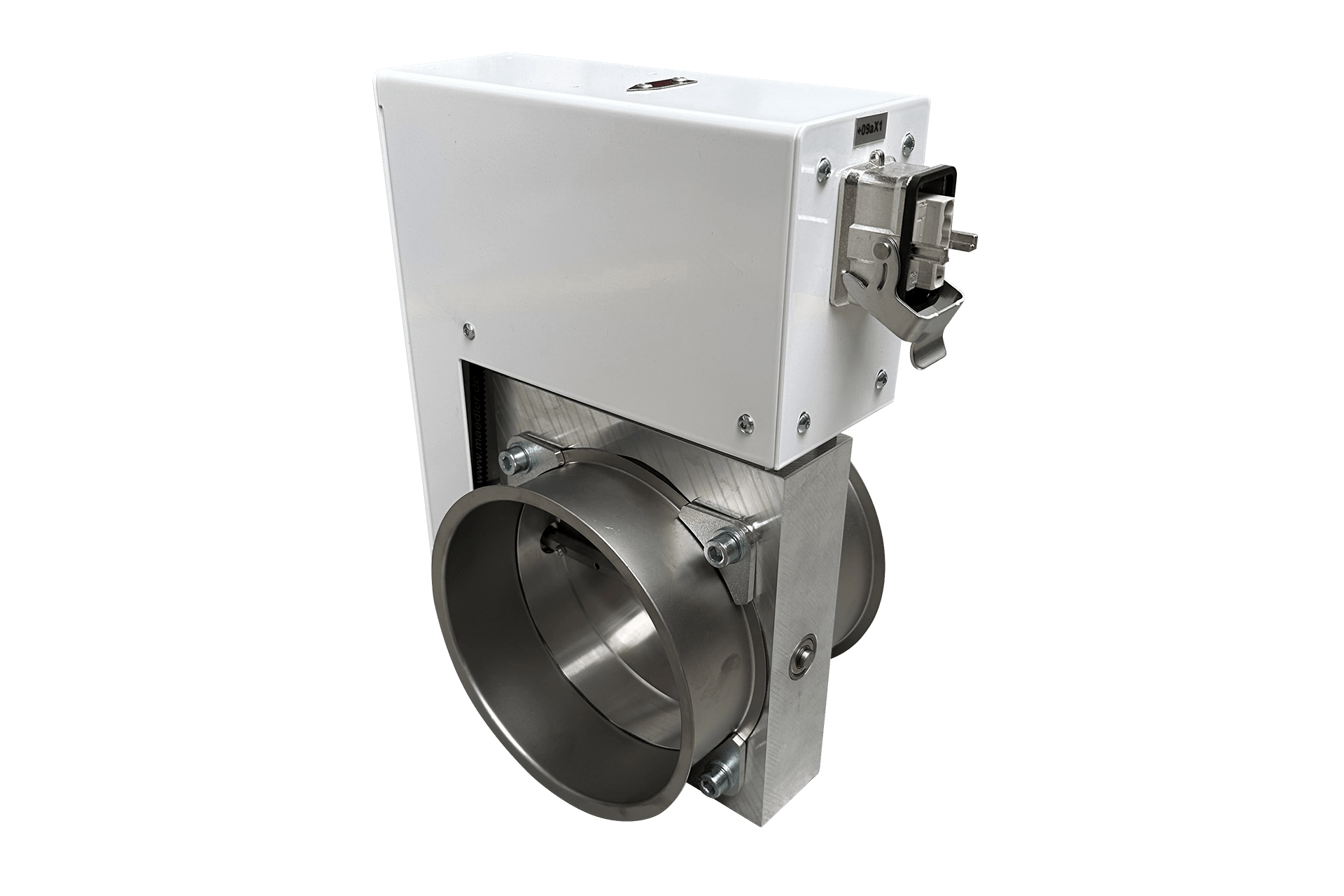

The Kdesign IBC flap can be easily installed in the IBC exhaust air flow without any negative effects on durability.

Bubble/width control in three configuration levels

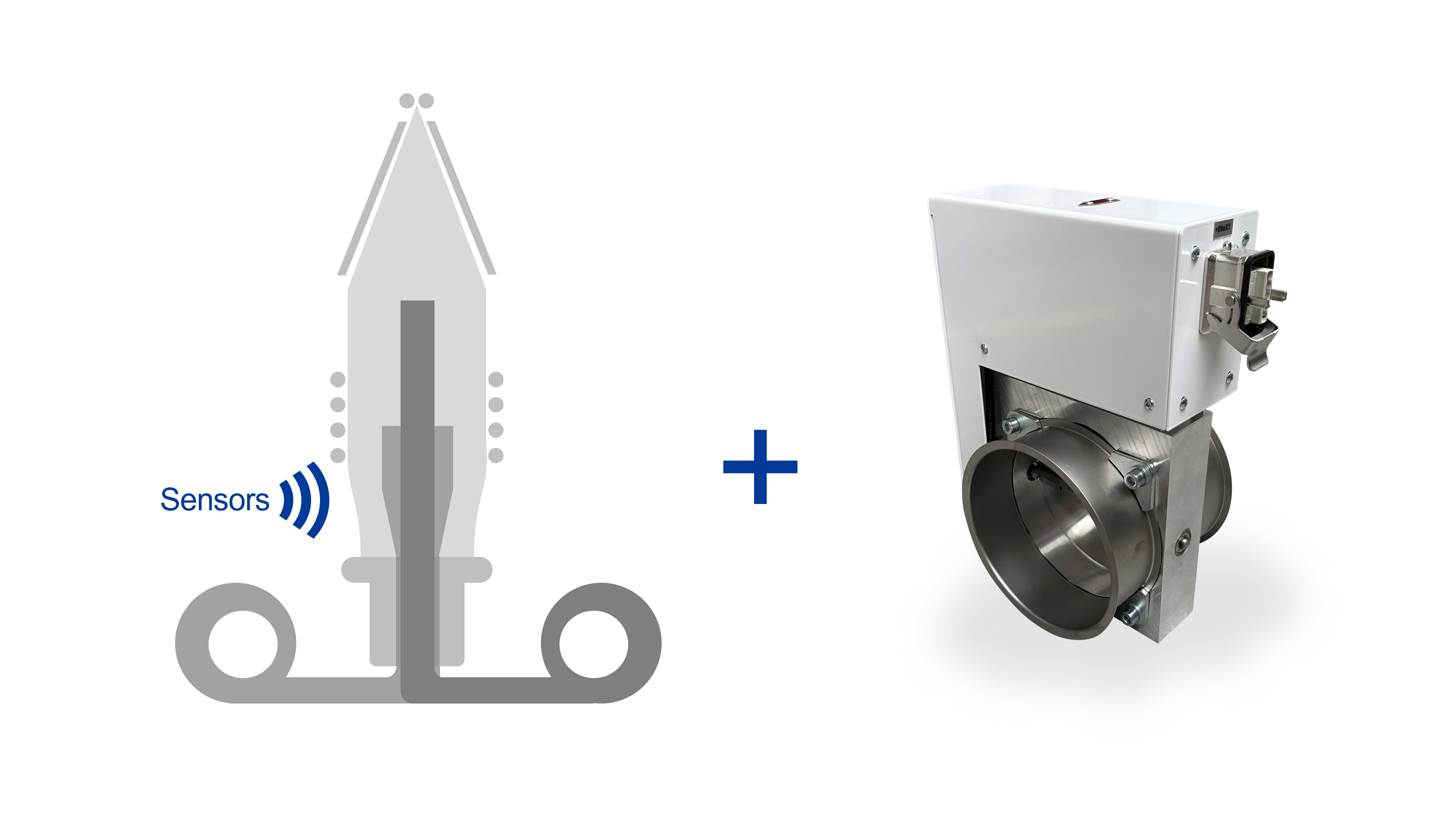

Basic bubble control

Stabilizes the bubble at the set diameter and also keeps the film width constant under constant conditions.

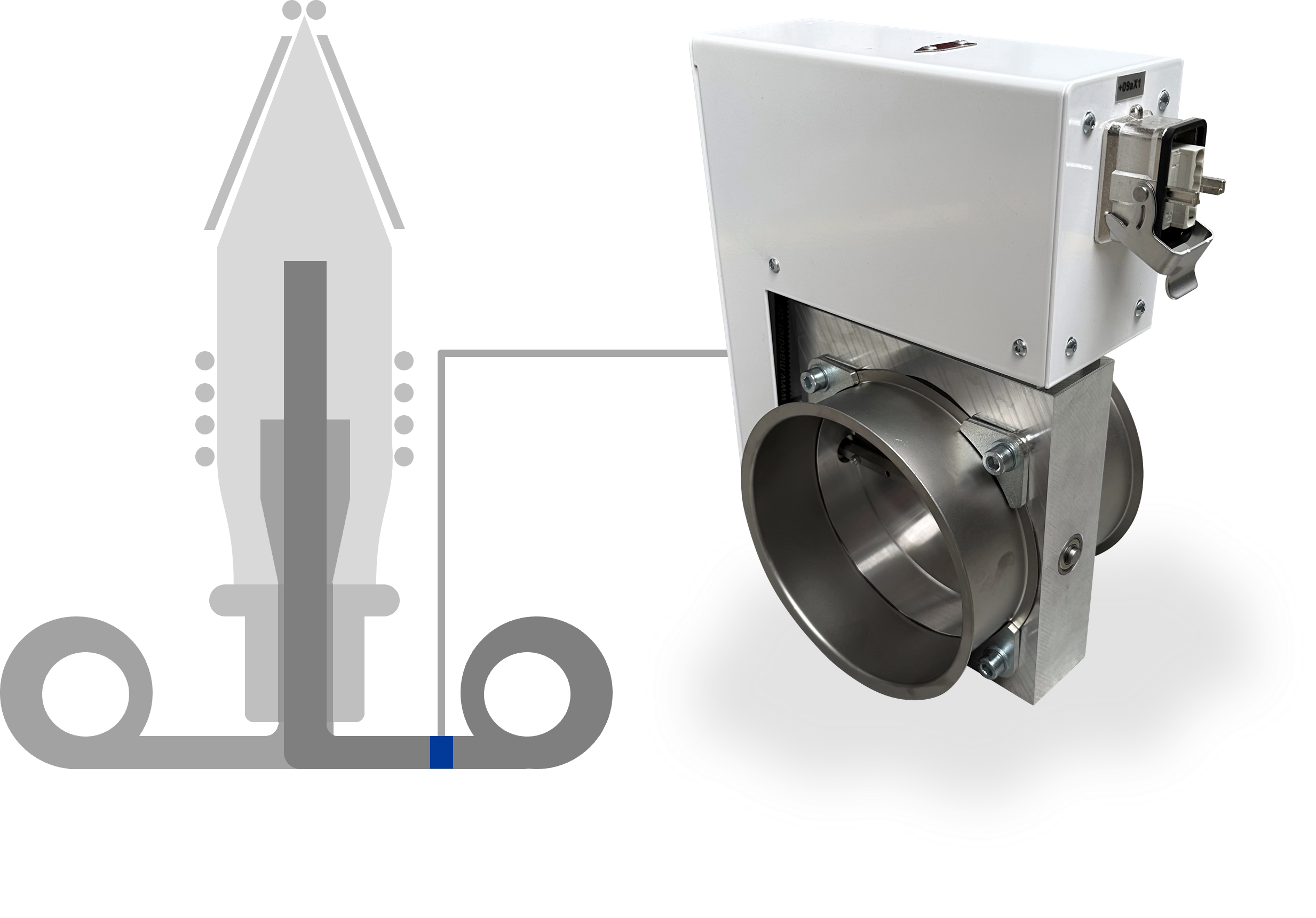

Consists of ultrasonic sensors below the calibration basket, a control unit and an IBC control flap.

The IBC control flap can be installed in either the supply air or the exhaust air. The additional integration of IBC blowers is possible.

The bubble diameter is determined by the diameter of the calibration basket; the bubble follows the moving sensors.

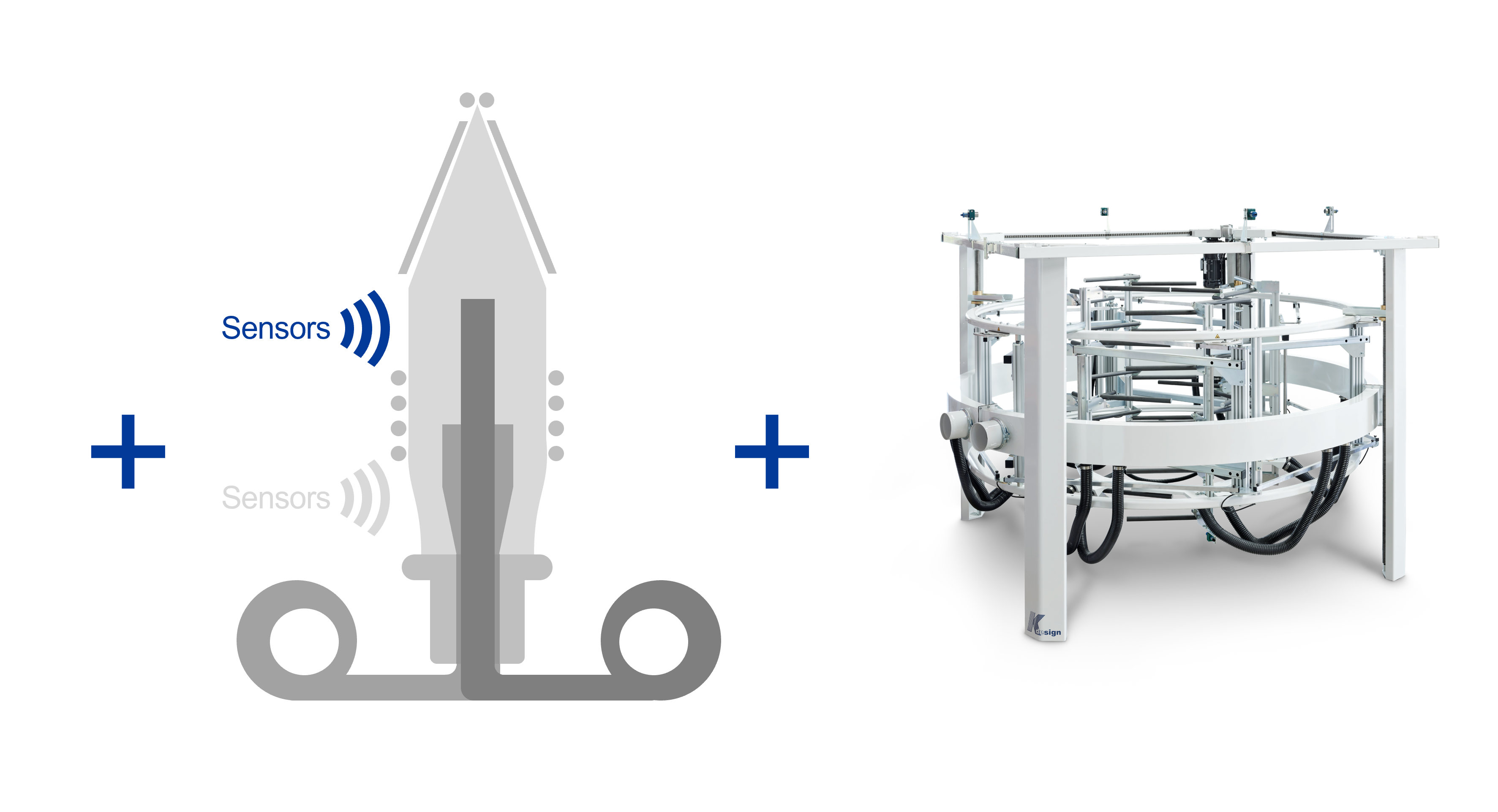

Standard width control

Extends the “Basic” bubble control with sensors above the calibration basket, which monitor the diameter of the film bubble.

The bubble diameter above the basket and therefore the film width are kept constant by finely adjusting the calibration basket diameter. This automatically compensates for shifts in the frost line height and prevents the film width from drifting.

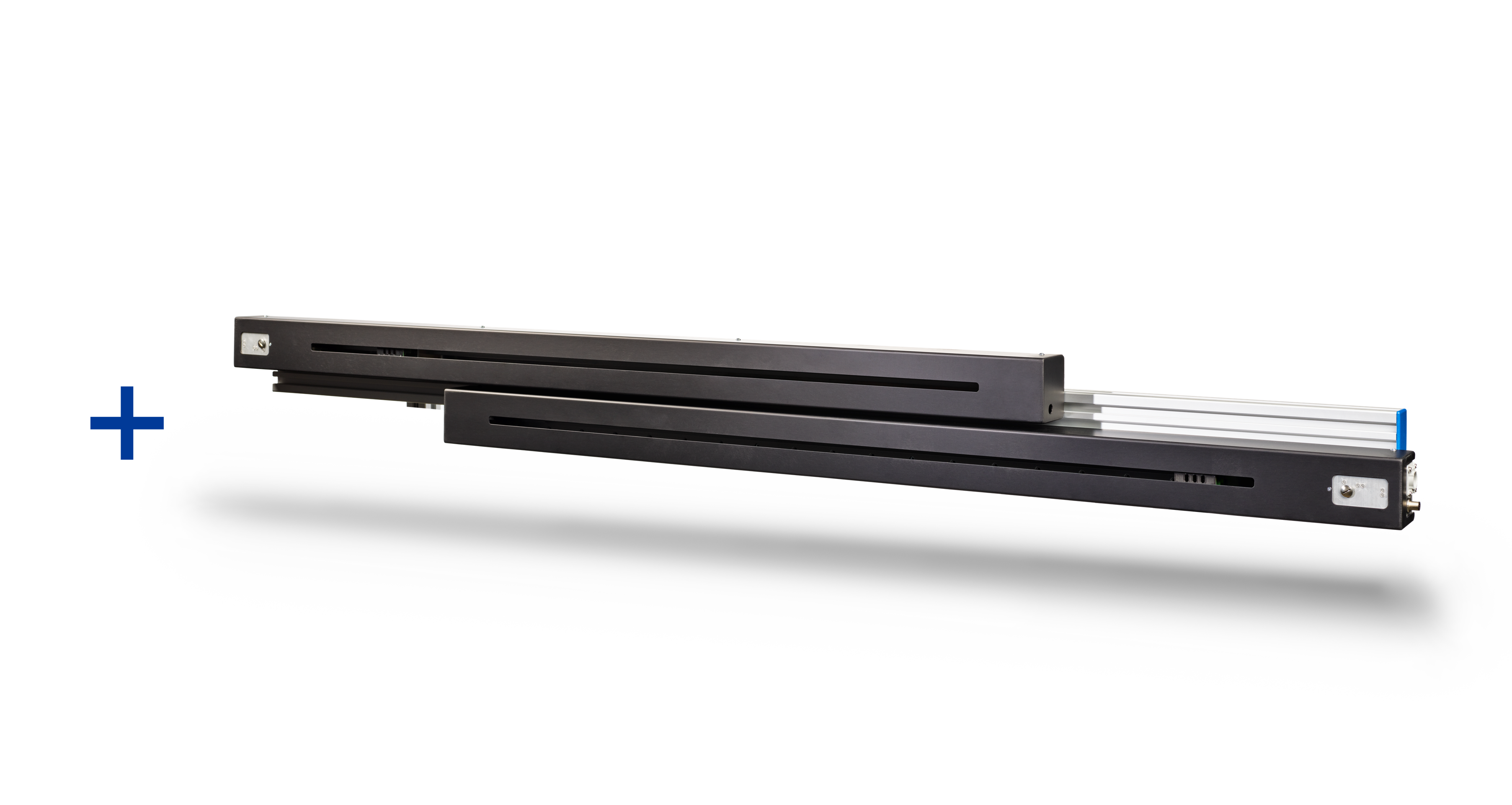

Premium width control

Extends the “Standard” width control with an additional width measuring bar.

This enables the system to determine the post-shrinkage from the basket to the flat area itself and calibrate the bubble diameter to the actual flat width for each production run.

Our “Premium” width control system offers clear advantages over width control systems that work exclusively with width signals from the flattened area (measuring bar or edge control). The very short distance between the measuring bar and the edge control system makes it possible to calibrate the bubble diameter for each production run.

Installation in the IBC exhaust air flow

Installing the control flap in the IBC exhaust air leads to significantly improved control behavior.

In contrast to control flaps from other manufacturers, the control flap from Kdesign is specially designed for use in the IBC exhaust air flow. Among other features, the actuator is thermally decoupled from the flap, which ensures the long-term durability of the control flap even under the high temperature conditions in the IBC exhaust air flow.

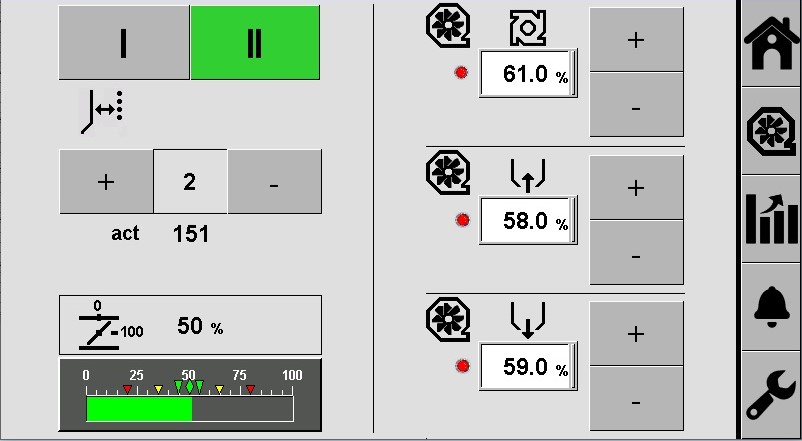

Easy operation via display

The Kdesign bubble control has a separate 7″ touch display. Operation is intuitive and you can keep an eye on all settings at all times.

For blown film line manufacturers, Kdesign naturally offers the option of direct integration into the line display.

Kdesign also offers width control for systems without air exchange via an IBC tower. With this solution, compressed air is fed into or discharged from the film bubble. We will be happy to advise you.