Calibration

Patented

Calibration

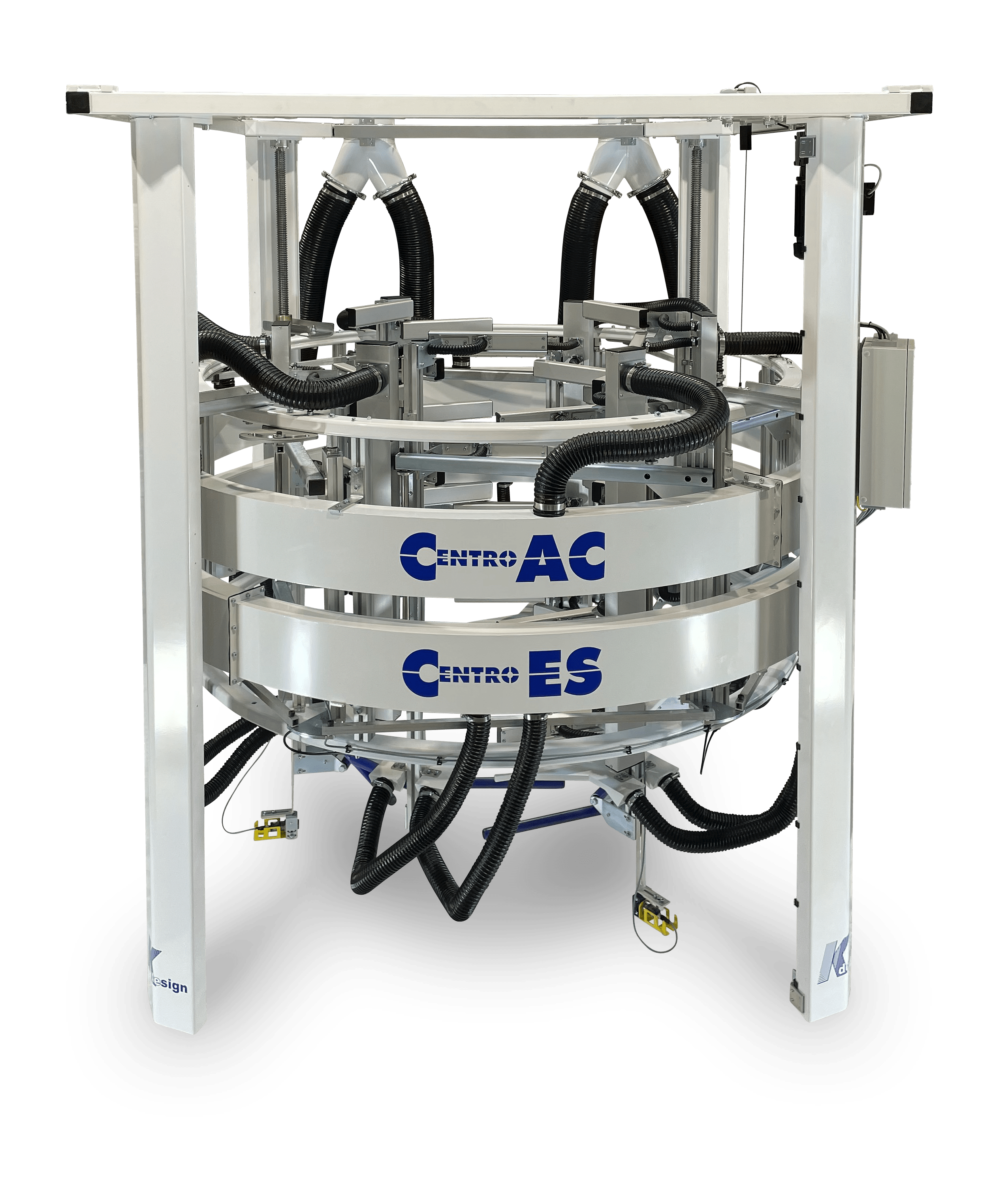

Calibration baskets from Kdesign not only guide your film bubble, but also guarantee productivity and film quality. Kdesign offers unique solutions for this. From the frost line scanner to the patented monomer suction system to the air basket, you can tailor your calibration basket ideally to your requirements.

Best bubble guidance

CENTRO calibration baskets guide your film bubble optimally centrically and absolutely reliably at all times.

Best film

protection

With particularly smooth-running carbon rollers or even with the help of air cushions, you can produce extremely sensitive films safely and reliably.

Best

productivity

CENTRO calibration baskets have unique options that allow you to increase the productivity of your blown film production.

CENTRO-L

The linear swivel arm basket

CENTRO

The scissor basket

Options for increased productivity

Integrated frost line scanner

An incorrectly set frost line height causes many problems, such as width fluctuations, production instability, basket markings or deviating mechanical film properties.

System operators often have problems setting the visually poorly recognizable frost line correctly.

In addition to incorrect operator settings, influences such as changes in the ambient temperature (day/night), the cooling air temperature or the melt temperature lead to undesirable fluctuations or drifting of the frost line height. This is often only noticed when the product quality has already been impaired.

The new KDvision-Frost frost line scanner from Kdesign solves these problems and makes the frost line visible at all times.

The current position can be seen on a clearly visible LED strip on the device and is also displayed as a numerical value and trend. If the position runs out of a defined monitoring window, an alarm is triggered.

The operator can implement production specifications precisely during the set-up and avoid setting errors.

In conjunction with a new blown film line, the KDvision frost is a further building block for the digitalization of the production process and the basis for monitoring, long-term archiving and control loops for keeping the frost line constant.

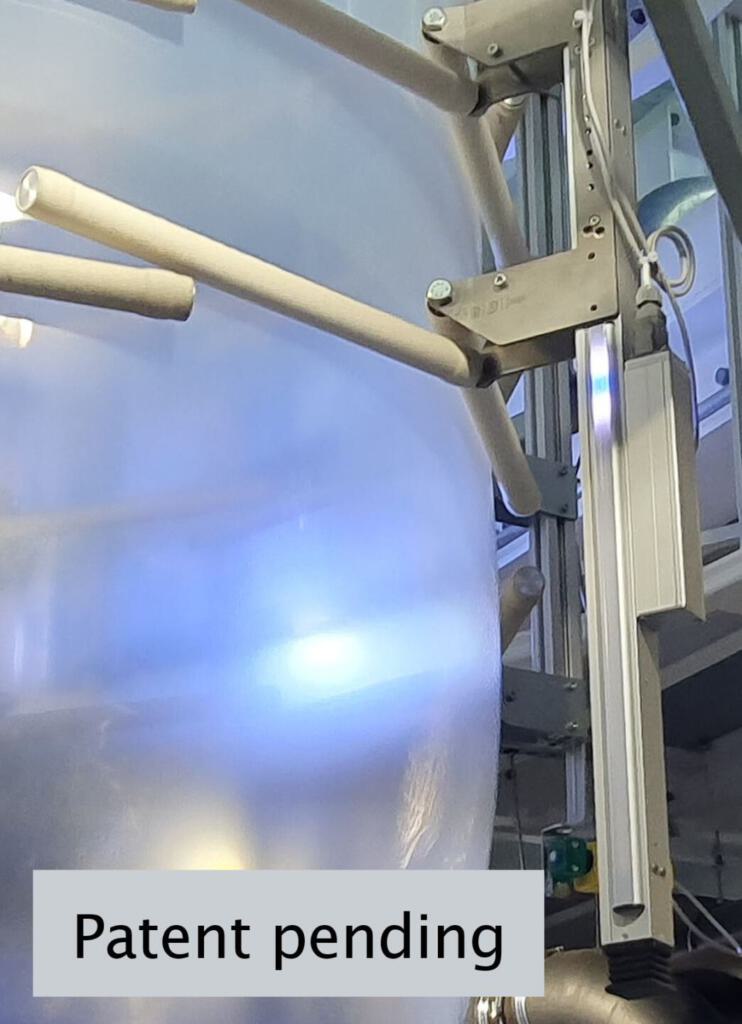

Monomer suction system

Contamination from monomers is not only hazardous to health, it can also contaminate parts of your system (e.g. sensors) to such an extent that time-consuming cleaning is necessary.

This problem can be avoided with the patented monomer suction system from Kdeisgn, which is integrated into the calibration basket. This saves you cleaning time and improves work safety in your plant.

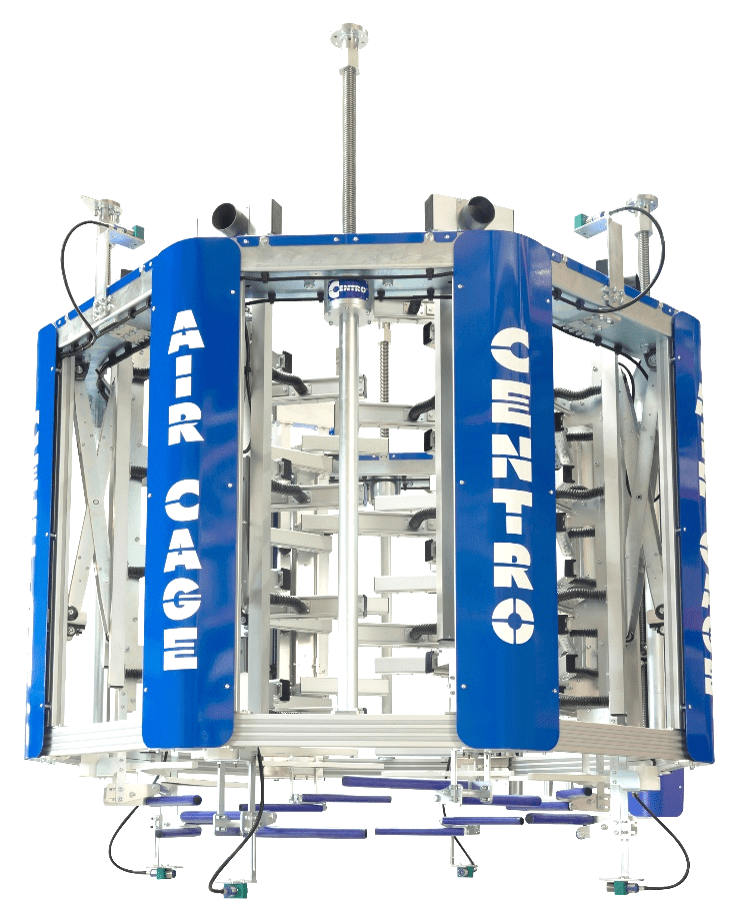

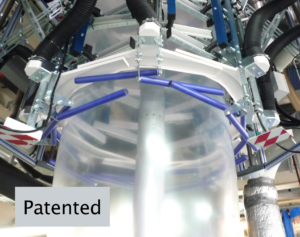

Air cage

Air baskets from Kdesign guarantee the best possible protection for your film. The blow-out elements reliably ensure a constant distance between the basket and the film.

Kdesign air baskets are particularly low-maintenance. Thanks to the sophisticated air flow within the air outlet elements, they do not become blocked during operation.

Integrated lifting device

Lift up to 500 kg with the calibration basket and make maintenance and cleaning work on the cooling ring easier.

A special design of the CENTRO-L calibration basket enables simple and ergonomic lifting. There is no risk of damage to the calibration basket or the system, as a slip clutch prevents overloading.

Smooth-running carbon fiber rollers

Kdesign offers particularly smooth-running rollers made of high-quality carbon fiber for all calibration baskets and supporting baskets.

Kdesign also offers supporting baskets in all sizes.