Cooling

Patent pending

Secondary cooling

With the CENTRO-Freeze, you avoid blocking of film in the haul-off by additionally cooling the bubble before it enters the flattening process. By using the CENTRO-Freeze, you can increase your output, save on anti-block additives and improve the film properties.

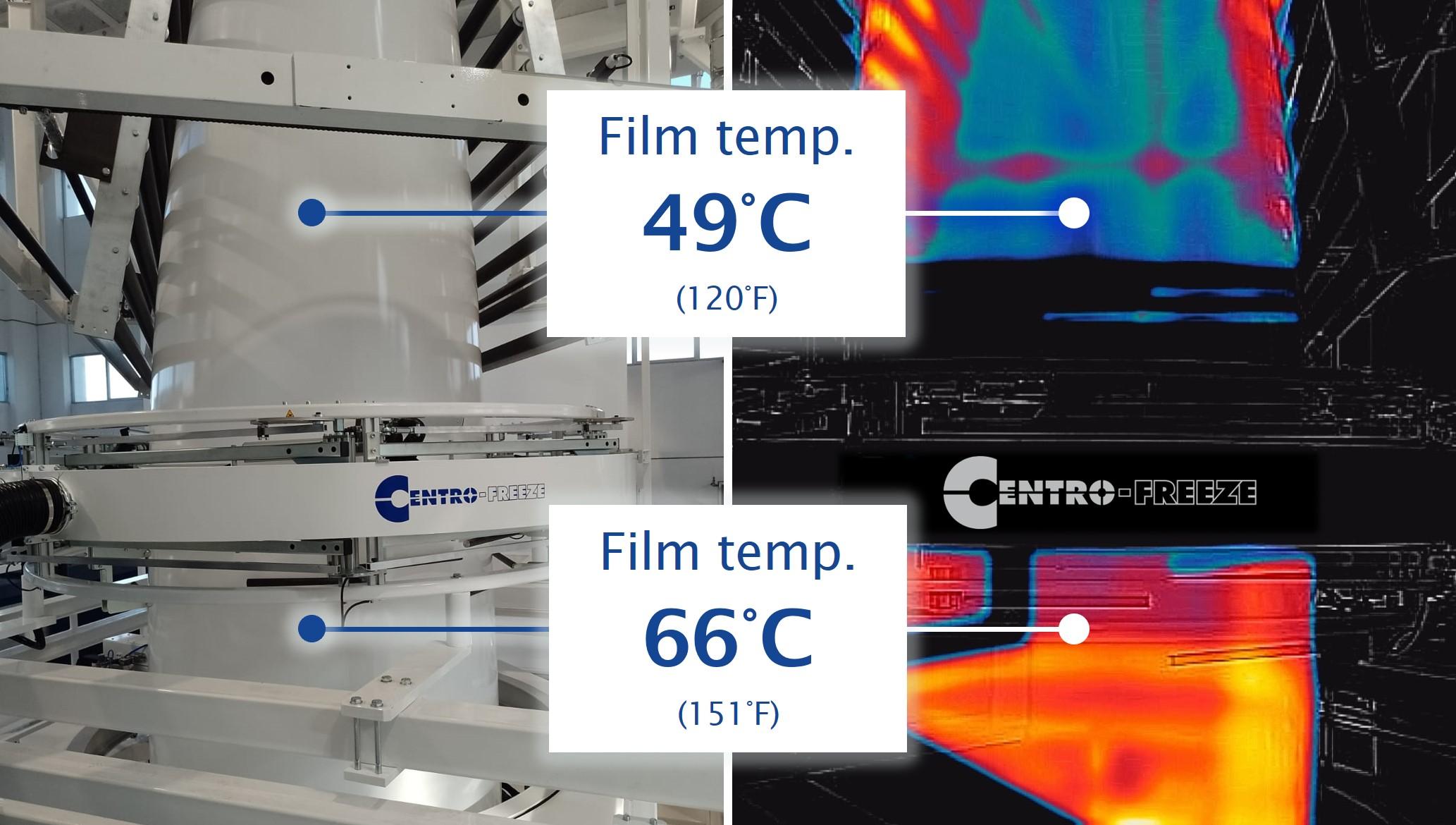

With the optional digitalization package, you can always keep an eye on the film temperature before and after the CENTRO-Freeze and can keep the film temperature at a constantly low level before flattening.

The CENTRO-Freeze is available for new systems as well as for upgrading existing systems. We will be happy to advise you.

Reduces

blocking

The CENTRO-Freeze cools your film before it is laid flat and thus prevents the film from blocking.

Saves anti-block additives

Thanks to the CENTRO-Freeze, you can save anti-block additives in your recipe and thus cut costs.

Increases

your output

With the CENTRO-Freeze, you can always run at maximum output even in hot ambient temperatures or at low ceiling heights – without blocking of the film.

°C film temperature

More output and lower costs

+15%

More output

(average)

Eliminiation

of antiblock

Produce more economically

With the CENTRO-Freeze, you can increase the output of your blown film lines by an average of 15%. At the same time, you can greatly reduce or even eliminate the proportion of anti-block additives in the film formulation.

These results have already been proven by numerous customers.

Customer 1 (Italy; PE films):

- Increase in output by 19%

- Anti-block reduction from 5% to 1%

Customer 2 (USA; FFS films)

- Increase in output by 16%

- Anti-block reduction from 5% to 0.5%

- Improved measured values in the drop test

Customer 3 (Germany; PE films)

- Increase in output by 14%

- Elimination of anti-block additives

Saving ceiling heigth

More cost-effective construction of new halls and utilization of existing halls

New lines equipped with a CENTRO-Freeze require a lower design reserve for the hall height. The CENTRO-Freeze reduces the required post-cooling zone, which determines the height of the hall in many applications.

This saves you construction costs and avoids approval problems for new production halls.

You are also able to install new systems in low existing halls with no or significantly lower output limits.

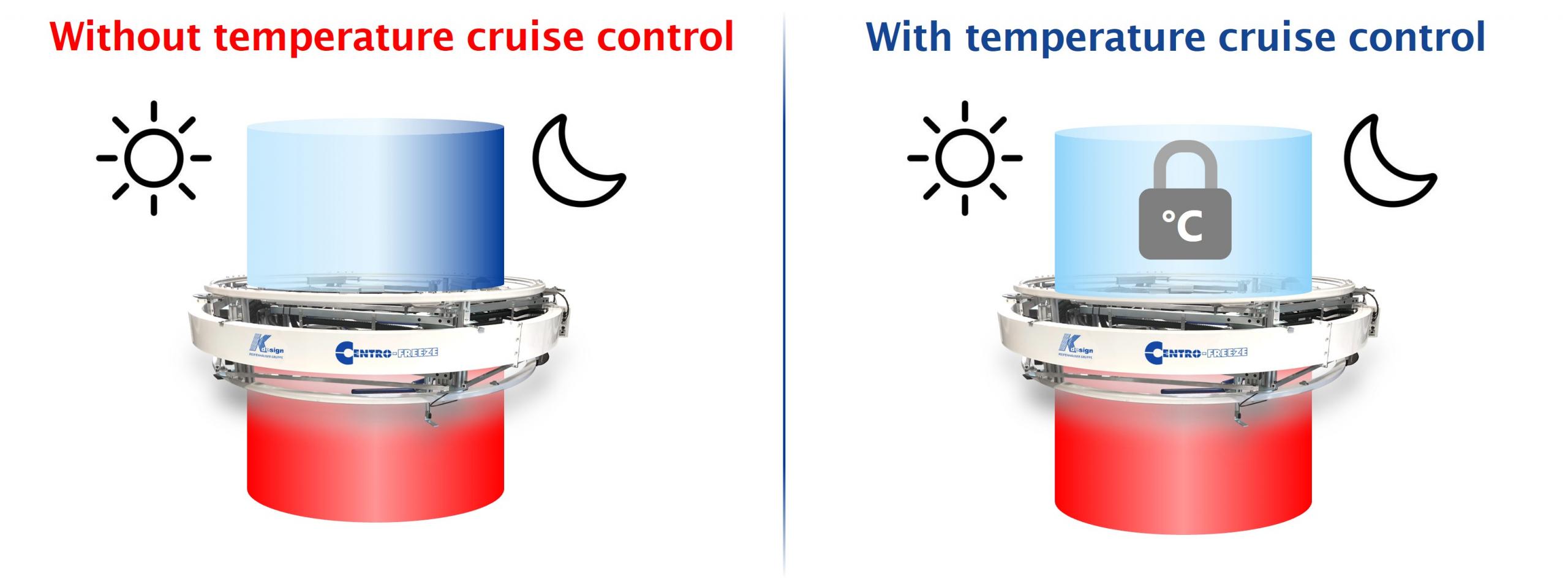

Automatic temperature stabilization

The “film temperature cruise control” function automatically compensates for changes in the ambient temperature (e.g. day/night fluctuations) and changes in the incoming film temperature. This means you always maintain constant production parameters and never cool more than necessary – which saves energy costs.

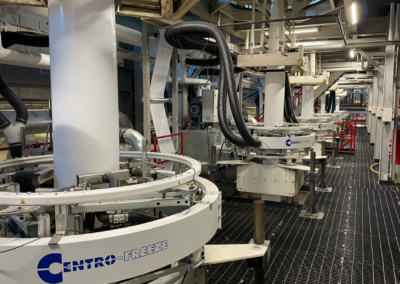

Space-saving installation

Can be retrofitted, even in tight spaces

The CENTRO-Freeze is the most space-saving post-cooling solution on the market. It can also be retrofitted in existing systems with very limited space.

This is because the CENTRO-Freeze has integrated roller guide elements and therefore replaces the support basket.

Digitalization of production

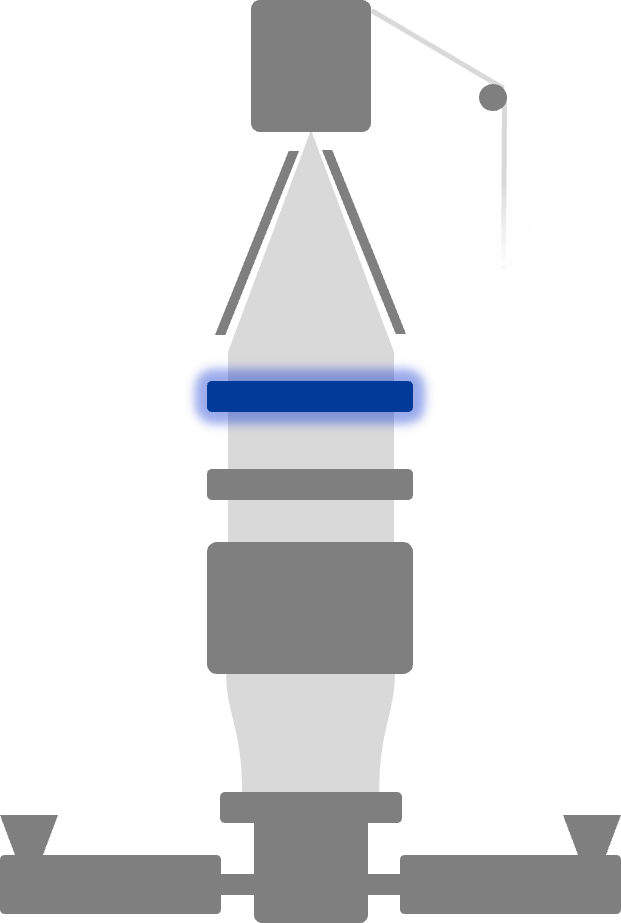

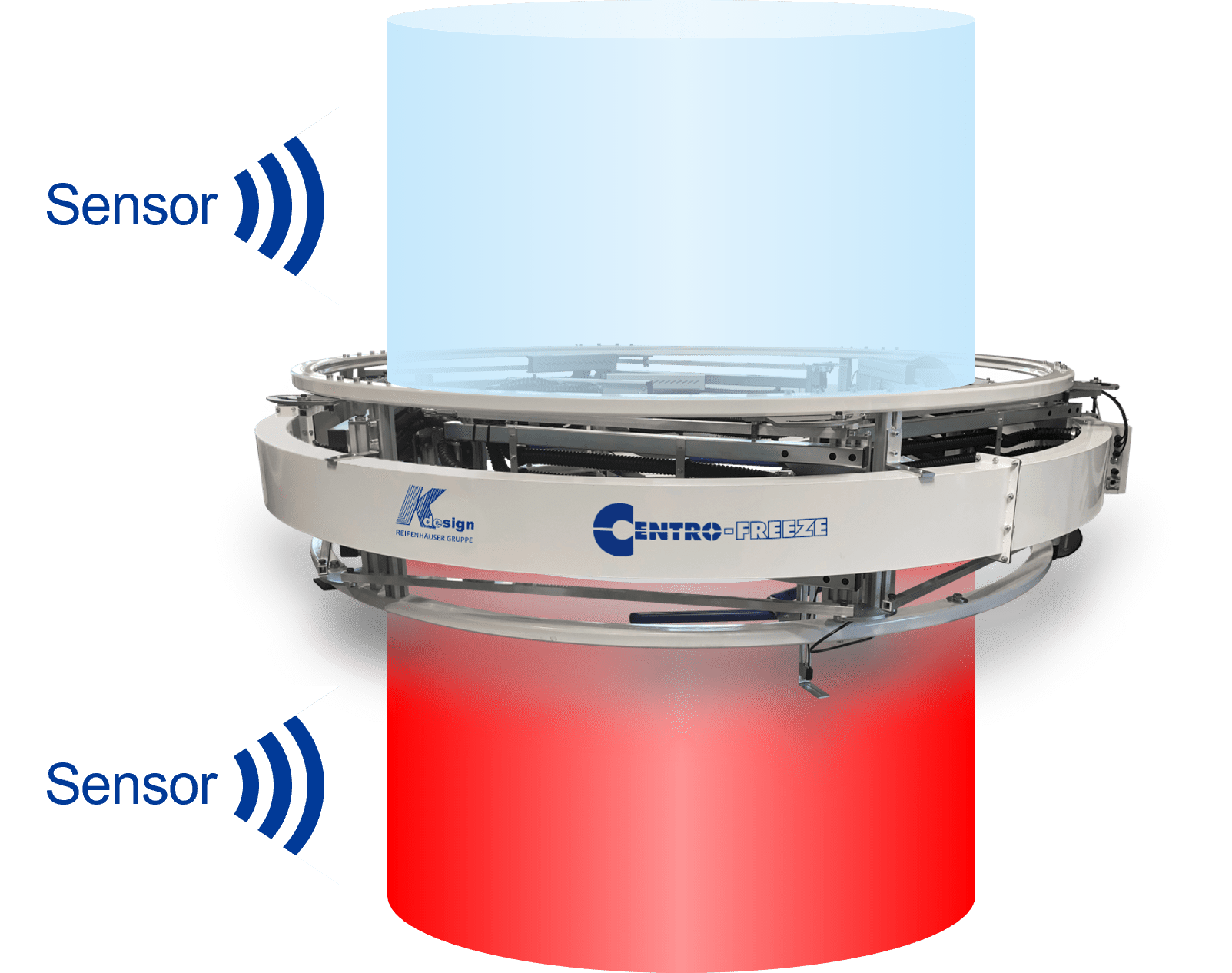

Measuring the film temperature before and after the CENTRO-Freeze

The CENTRO-Freeze is equipped with a sensor package that allows you to keep a constant eye on your blown film production. The sensor package includes infrared temperature sensors, which are fitted before and after the CENTRO-Freeze. This allows you to track how much temperature the CENTRO-Freeze is extracting from the film at all times.

Additional sensors for recording the pressure and temperature of the cooling air complete the recorded data and ensure reproducible settings.

Control circuits are available for keeping the bubble temperature constant at the outlet and for diameter tracking.

Kdesign also offers the option of placing any number of additional infrared temperature sensors in the line and displaying this data as well.

Advantages at a glance

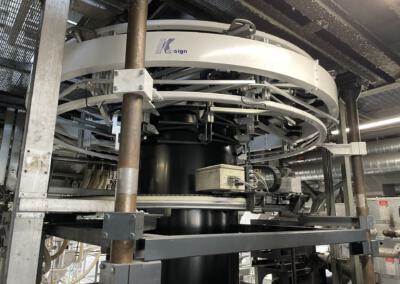

Advantages over classic secondary cooling rings

The CENTRO-Freeze is variable in diameter. This means that the distance between the cooling elements and the film bubble is constant for all film formats. The cooling elements can automatically follow the film bubble diameter. This saves you tedious changeover work in areas that are difficult to access when changing formats.

The CENTRO-Freeze opens up post-cooling for systems up to 4000 mm wide.

Advantages over competitor systems

CENTRO-Freeze integrates the two functions of cooling and film guidance and therefore replaces the supporting basket. The CENTRO-Freeze is therefore particularly space-saving and can be easily retrofitted to existing systems. Due to the low height of the CETNRO-Freeze and its cooling capacity, new systems require a lower ceiling height.

The centric positioning of the cooling elements in relation to the film bubble means that 100% of the cooling air actually reaches the film bubble at all diameters. Competitors use cooling elements integrated in swivel arms. This has the disadvantage that a large proportion of the cooling air bypasses the film bubble, especially with small film bubble diameters. For this reason, the CENTRO-Freeze cools more effectively and is significantly more energy-efficient than competitor systems.

Advantages through digitalization

The CENTRO-Freeze offers a digitization package that is unique on the market. The package includes multiple sensors which, among other things, record the film temperature before and after the CENTRO-Freeze. This allows you to see at all times how much heat the CENTRO-Freeze is extracting from the film.

Intelligent control allows you to keep the film temperature at a constant level and precisely reproduce previously tested production points.

In addition, you can expand the CENTRO-Freeze with any number of freely positionable infrared temperature sensors. This allows you to monitor the film temperature in your entire blown film line.

Summer is coming

Especially in the warm season, output rates often have to be reduced due to blocking problems. This not only makes it harder to plan your production. The increased addition of anti-block additives also makes your products unnecessarily expensive.

With the CENTRO-Freeze, you can reliably avoid blocking problems, reduce your production costs and improve your adherence to customer deadlines.

Make sure you get your CENTRO-Freeze before the next hot season.